An Update on Hardrock Mining in Montana

Synopsis of the January 5 Presentation by Garrett Smith, Montana DEQ

by Andy Thompson, MSDC Secretary

Garrett Smith, a geochemist with the Montana Department of Environmental Quality (DEQ), treated MSDC attendees to an overview of present-day hardrock mining in Montana. This included his DEQ division’s current permitting actions and a photographic tour of selected mining sites throughout the state.

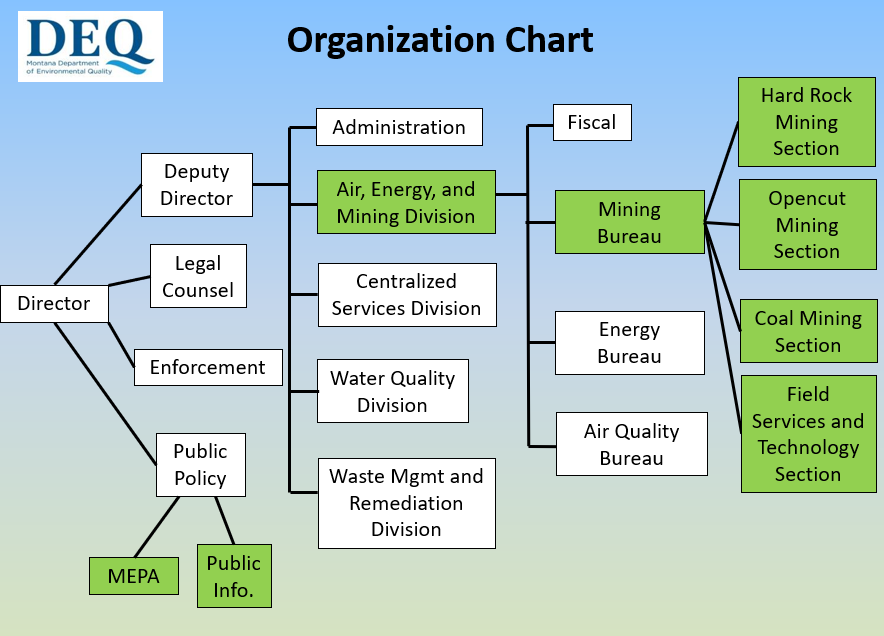

Montana’s DEQ has five major divisions, as shown in the middle column of the organization chart below. The Mining Bureau’s Hard Rock Mining Section, in the upper right column, is highlighted in green. Garrett noted that the section does not have responsibility for coal, open-cut mining, or field services.

Legalities Related to Hard Rock Mining

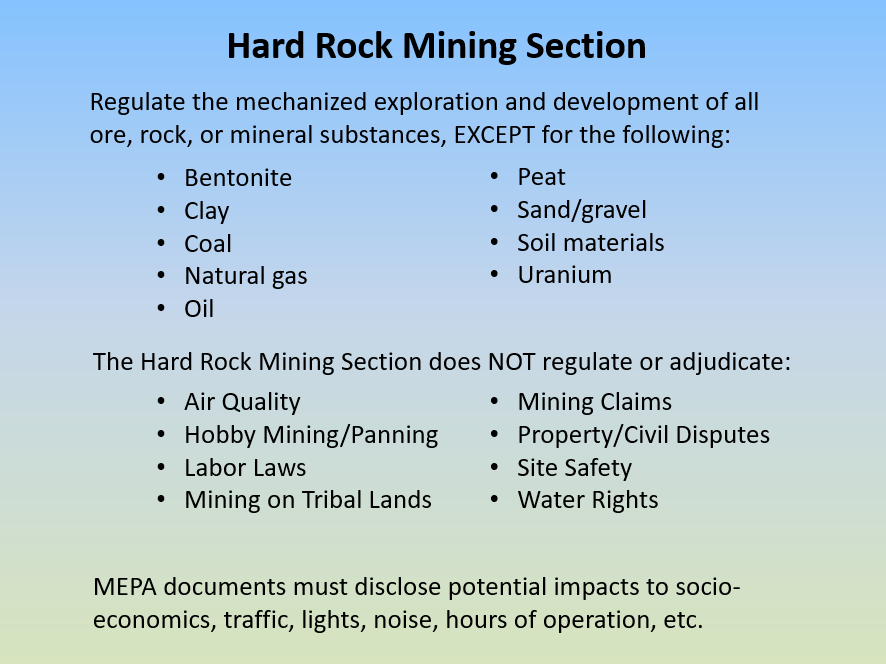

The Hard Rock Mining Section regulates permits for mechanized exploration and for the development of all ore, rock and mineral substances, except for those identified in the slide below. The slide also spells out DEQ functions not handled by the Hard Rock Mining section.

The good news for mineral collectors is that there is no need for hobby-level collectors to obtain a permit for small-scale collecting or panning. Even if the collectors want to work on a small piece of property, less than five acres, they can apply for a small miner’s exemption. This is not a permit as such, but allows commercial mineral extraction to occur at a small scale so long as air and water quality are protected. A separate licensing process is available for exploration activities.

An important function of the Hardrock Mining Division is to evaluate the potential environmental impacts of a proposed large-scale mining operation before any such operation may begin. Further, the DEQ requires mining firms to purchase a financial assurance bond which is held by the state of Montana. If the mining firm does not complete the agreed-upon reclamation, the state will use the financial assurance funds to make sure the affected property is restored appropriately.

Garrett explained the diverse types of permits and noted that a large part of his work is putting together the operating permits. That includes preparing environmental impact statements. This permitting process often takes about two years. The work is done in close collaboration with the public and sometimes with federal agencies such as the National Forest Service.

One advantage of working on permits for large rock-mining operations is that often the material is sold as is, such as for decorative stone. Typically, this type of rock does not contain sulfides and does not require chemical treatment. As a result, there is no acidic runoff or other types of pollution associated with this type of hardrock mining operation.

Distribution and Type of Hardrock Mines

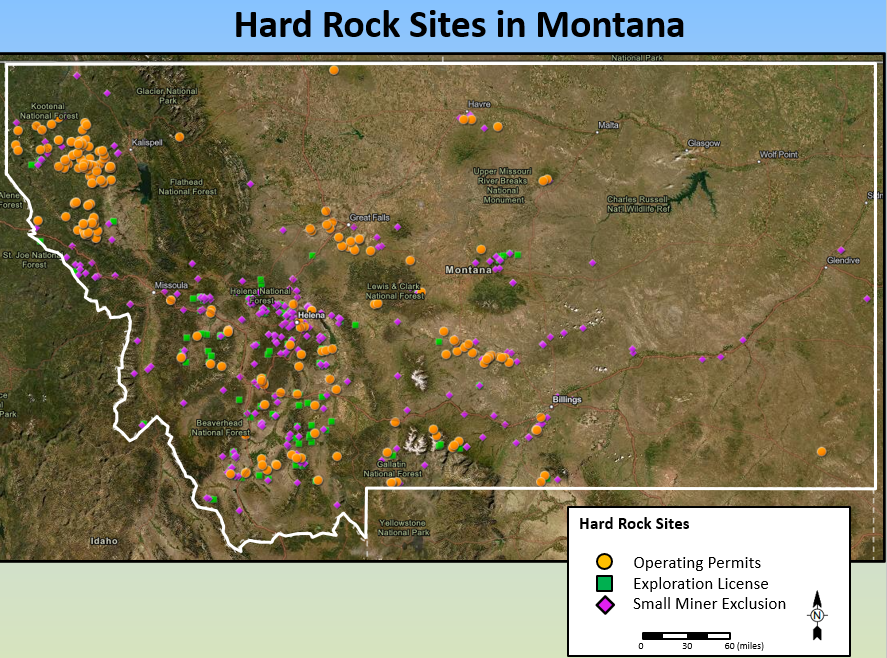

The very informative slide below provides an overview of the hardrock mining sites taking place across the entire state.

The western third of the state, being mountainous, consists of a lot of volcanic and metamorphic rock. This is where most of the hardrock mining operations are found as indicated by the orange circles. The green squares pinpoint the fewer sites that have been permitted for exploratory mining. The pink diamonds indicate small mining exclusion sites.

The middle third of the state is mostly rolling plains, but there are a few protrusions of hard rock operations as indicated by the several clusters of orange circles. These locations often contain interesting minerals including gold and silver.

The eastern third of the state is largely flat, sedimentary material where coal mines, oil, and gas are found. This third contains very few hard rock mining sites.

Next, Garrett addressed the question of which types of minerals the above hardrock operations have been mining. He indicated that when one looks at the permits, it is clear that the most common type of permit is for the general category of “rock products” (n=200). The total number of permits issued has been less than 40 for all of the other nine categories of commodities combined. The number of permits for individual commodities ranges between 2 and 15, including base metals having 7 (typically referring to lead, copper, nickel, aluminum, and zinc), gold and silver (n=15), and a smaller number of permits for limestone, talc, palladium, platinum, garnet, sapphire, and miscellaneous other commodities.

Only about half of the hardrock sites are still active. The remainder of the hardrock sites are either closed or undergoing active reclamation. Many of the precious metal and base metal sites such as copper are closed. But many of the industrial metal sites such as platinum are still in production.

Examples of Hardrock Mines

At this point in his presentation, Garrett pivoted to share a treasure trove of photos of selected mine sites and explanations of what is actually happening at many of the mines.

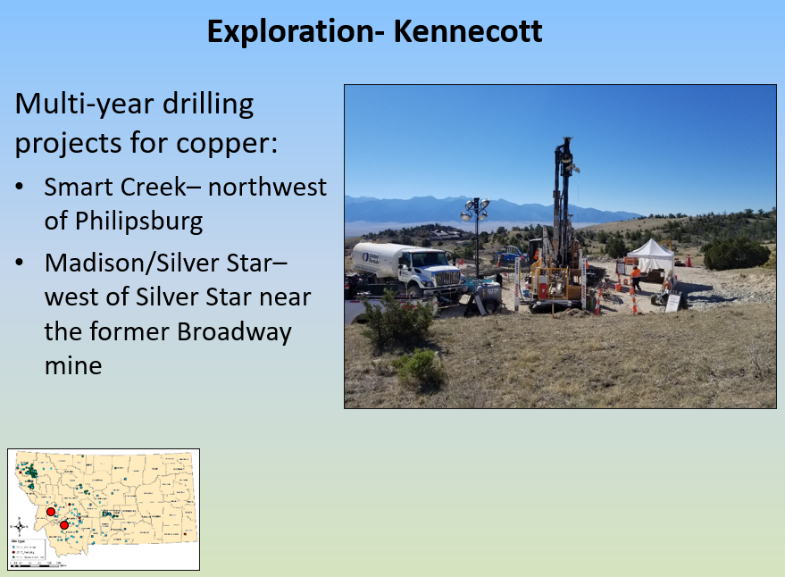

Kennecott has two exploration projects in the state – an example of a drilling site is shown below. At the lower left of this photo and most of the following photos, there is a map of the state with a red dot that shows the location of the operation being discussed.

The Berkeley Pit, Butte Montana

The famous Berkeley Pit copper mine was operated historically by the Anaconda Copper Company. A new operator, Montana Resources LLP, has for decades successfully mined copper and molybdenum from the nearby Continental Pit, while the historic Berkeley Pit has filled with groundwater.

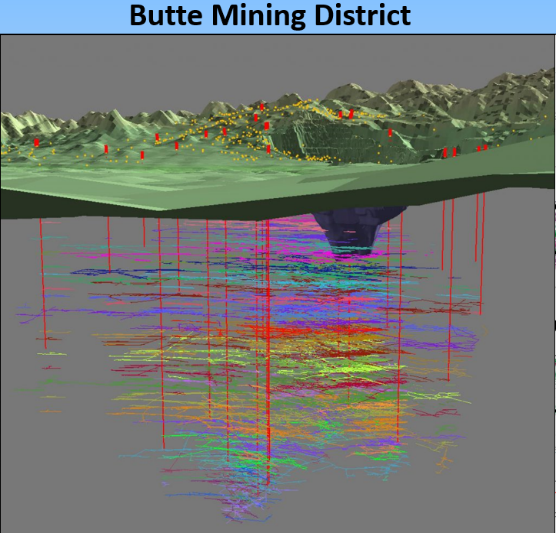

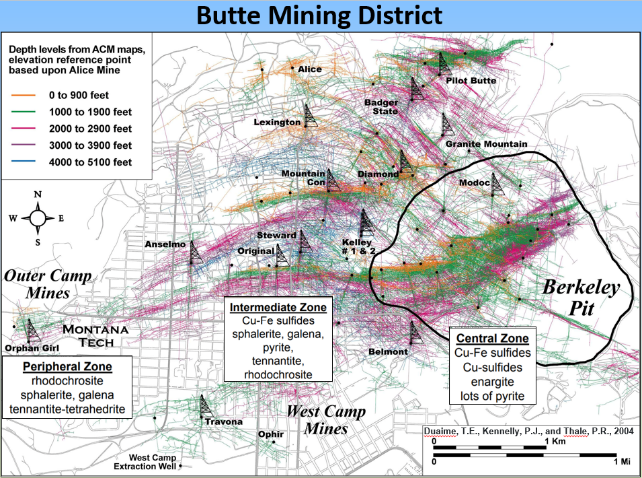

Below is a sketch of the Butte copper mining district with its diverse levels and shafts. The black cone-like area, beneath a green surface, indicates the location of the Berkeley pit, the rich source of copper.

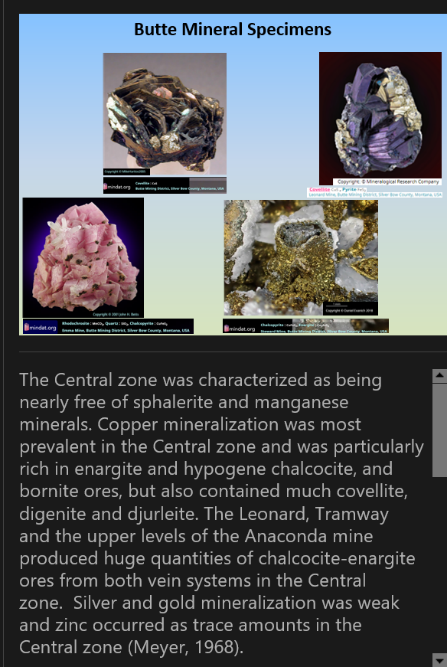

Beyond copper, the photos below show some of the additional mineral specimens that have been extracted from various parts of the mine. Copper was found in what became the main central region. Rhodochrosite and other minerals were found in much smaller quantities in the more peripheral western area.

Golden Sunlight Mine

The reclamation program at the Whitehall gold mine (Golden Sunlight) open pit mining ended in 2019. The reclaimed area now looks as pictured below.

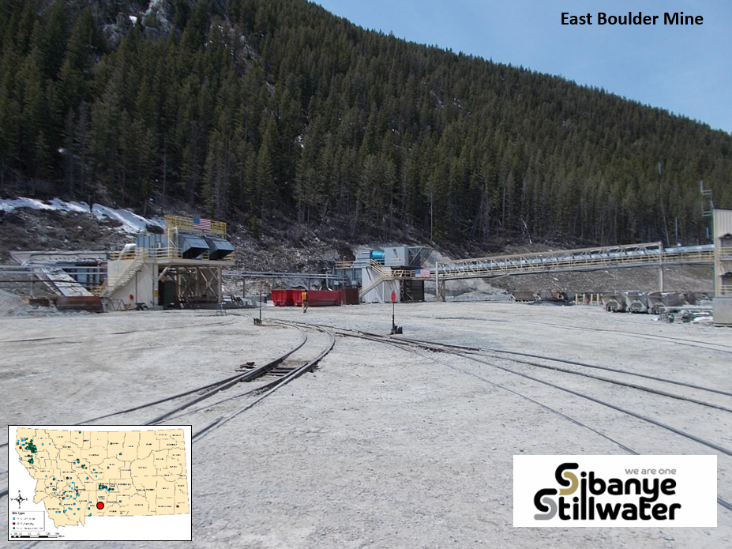

Stillwater Platinum & Palladium Mine

The third site was the Stillwater Company’s platinum and palladium mine in South Central Montana (see the red dot)

Troy Mine

The Troy Mine in the northwest corner of the state was producing silver and copper for decades. But since about 2018, the mining operation ceased and the property went into its reclamation phase. This required a three-phase approach:

· capping the mined area of tailings (2018)

· deposition and grading of soil

· planting vegetation (2021)

Below is a photo of phase one after soil has been added atop the mine tailings and properly contoured.

After three years, as of 2021, we see below the third phase, the vegetation. It is literally blossoming. This third reclamation step will be followed by planting trees.

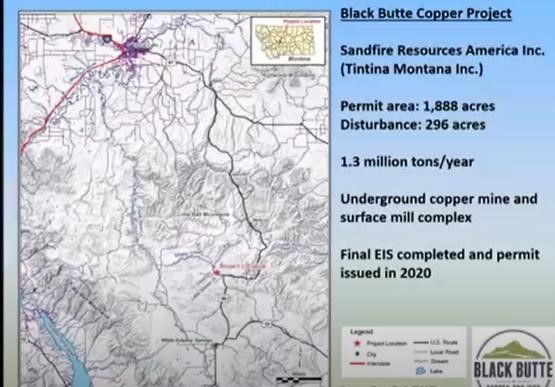

Black Butte Copper Mine

Another mining project, located in the central part of the state, has a component that makes it unique from the others Garrett described.

This mine operation illustrates the typical time it takes a mining operation and State DEQ from the initial proposal stage (2018) to the final approval stage (2021), in this case 3 years. As of early 2022, the mining operation had not yet started

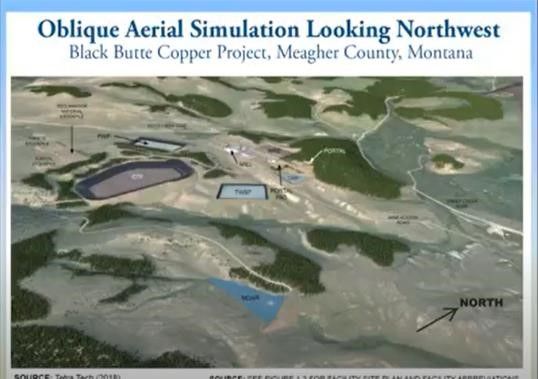

The Black Butte Copper Project is designed so its tailings impoundment, shown to the upper left of the image below, will have a somewhat rectangular footprint. What makes this unusual is the mine operators will dump tailings into the walled off area and mix in cement so there will be a solid mass with no tailings pond on top. This would prevent spills and toxic liquid elements from contaminating land and water resources.

The same protective technique will be used for the underground mining of its two copper seams, an upper and lower vein. As a segment of each seam is excavated, the empty space will be back-filled with a mixture of tailings and cement. As a solid, the newly filled-in area then poses less of a risk of contamination because there is no fluid.

Industrial Mines

Garrett then shifted away from describing the metal mines and turned to share information about some of the “industrial mineral mines.”

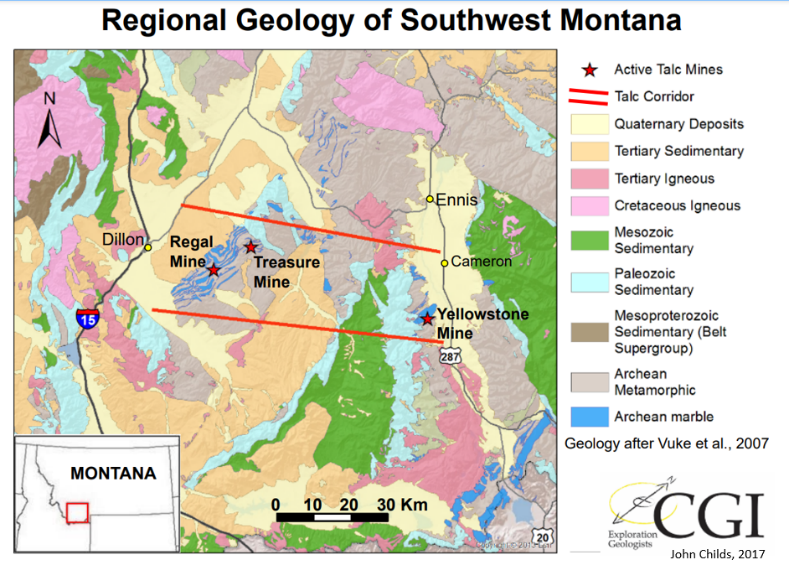

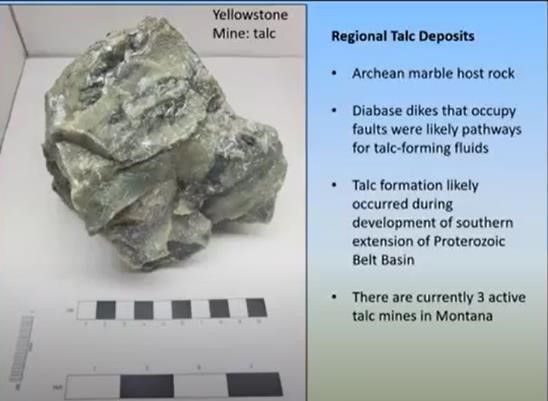

Yellowstone Talc Mine

His first example is the Yellowstone talc mine in the southern edge of the state bordering Idaho. One aspect of its interesting geology is that the talc was derived from the transformation of the ancient marble in the Regal Mine area pictured below. Over millions of years, hot water reduced the Archean marble (shown in blue) to talc, resulting in a present-day talc corridor, illustrated between the two straight parallel red lines. Garrett said that talc is used extensively in a wide variety of paper, plastic, and rubber products.

There are only three talc mines in Montana. Below is an example of a typical talc specimen.

Below are examples of dolomitic marble found in this area. The specimen on the left shows some large crystals of white and grey recrystallized marble that is sometimes found just off the edge of the main talc seam where the seam edges make contact with neighboring non-talc rock. Below and on the right is red dolomitic marble which has smaller crystal grains. It is used primarily for landscaping, including in the State’s capital city, Helena, the location of Garrett’s DEQ headquarters.

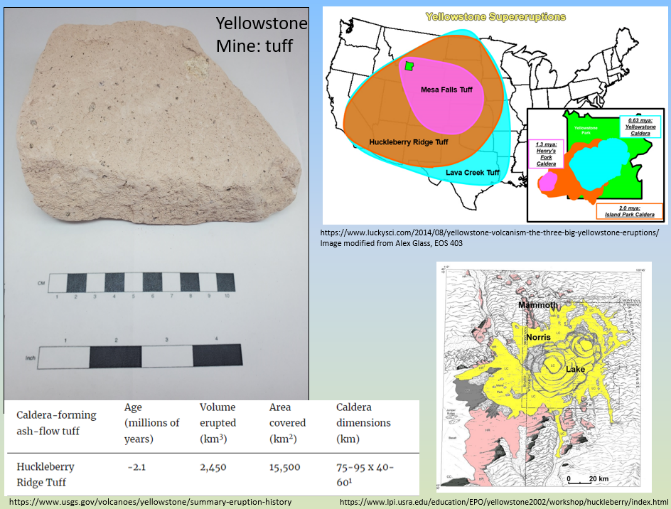

Garrett pointed out that near the above ancient talc deposit one can occasionally come across outcrops of much younger overburden, shown below as light brown. This light brown mineral is volcanic tuff deposited from the ash when Yellowstone’s hotspot erupted 2 million years ago. The pink and brown areas on the map below (top right) show the area of the very extensive eruptive volcanic plume that deposited tuff over almost the entire western half the United States.

Sapphires

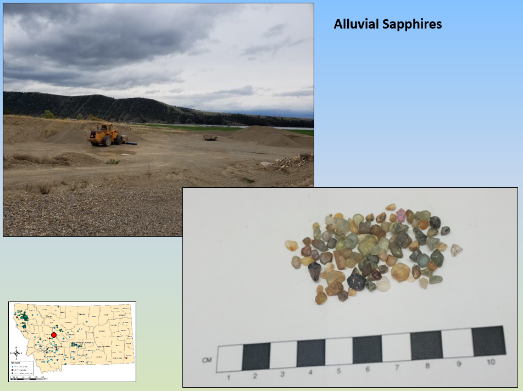

Mineral collectors readily associate Montana with sapphires. That is especially the case with the area of Phillipsburg. But the most highly treasured sapphires are the thick, flat, light blue Yogo sapphires. Other collecting sites include alluvial sapphires that were washed away from their original bedrock, as pictured below.

Garnets

Similar processes distributed garnets within alluvial settings that also hosted placer gold deposits. Historic garnet miners would often sort old dredge piles where gold had previously been removed. One modern Australian mining company traced the ancient path followed by those alluvial garnets back to their source bedrock. As such, those stones were angular and not rounded. So, when mined and crushed, with their intact sharp edges, they are well suited for industrial use as abrasion products.

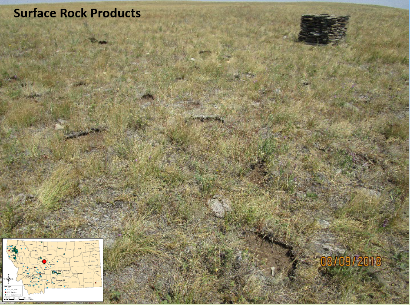

Other Types of Rock Products

The final chapter of Garrett’s story of Montana’s rocks focused on a wide range of types of rocks. At the simple level, individuals can simply uncover and pick these flat pieces of silt stone, mudstone or sandstone and stack them on skids, shown below, for diverse domestic uses such as home patios or paths.

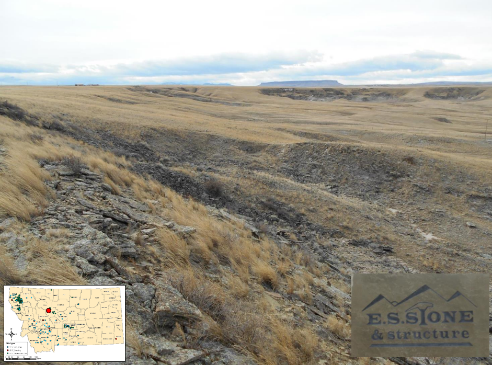

As pictured above, as one moves east and north, away from the hard rock western mountains, one finds flat plains that have small and shallow depressions of brown flat rock formations. That makes for easy collecting. As the process becomes more industrialized, businesses can search for outcrops that have abundant exposed flat rock formations (below).

Garrett mentioned that property values in Montana have risen considerably and so larger decorative stone slabs for housing and corporate landscaping features are now in high demand.

Industrial Rock for Construction Aggregate and Railroad Beds

As we move away from decorative rock and more toward industrial rock, the photo below shows a typical source for industrial gravels used for large scale operations such for railroad bedding and construction of dams and spillways.

The typical minerals used are from volcanic depositions and include shonkinite, a type rock for Montana. It, along with dacite, also shown below, are both very durable and used for heavy duty industrial needs. Other rocks, also of a conglomerate nature but less durable, also are used for highway bedding.

Question & Answers

Garrett concluded his presentation and Cindy invited questions. The first was about how individuals, say a farmer, could mine the flat rock for decorative or wall building efforts on his property. Garrett noted that no permit is needed for personal use. But, if he were to sell that rock to his neighbor, then such flat rock harvesting would become a mining activity and so the farmer would need to have a permit.

Another question concerned the Montana Belt group region which dates back over a billion years in age. Has that been a rich source of fossils? The answer was that this really old region has been found to have stromatolites similar to algae mats, but not fossils of the more complicated and later forms of life. That is due to the fact that this was the time when the Siberian and North American cratons were separating and it was being filled in with water and marine sediments. So the only type of life was simple aquatic forms. As a result, the Belt is not a significant source of fossils. The eastern part of the state is younger, flatter, and has more Cretaceous sediments. That is where one finds Montana dinosaur remains.

The questions continued and ranged into how well the mining companies have been complying with reclamation requirements (they are doing better these last 20 years), and how the bonding requirements are determined (in recent years, bonding requirements are set based on research findings about how best to enable vegetation growth, and a process that relies on detailed spreadsheets of all the projected expenses, annual monitoring, and retaining the mining companies’ bonds for longer periods of time).

Does the Montana DEQ run into problems of mines tunneling into areas they are not permitted to be in? Although that can happen, mining companies and neighbors do monitor each other. There have been lawsuits due to Canadian mine water running into Montana waterways and carrying their pollution south into the U.S.

How has the once heavily acidic Berkeley Pit mine cleanup of the pit lake water fared in the last ten years? Garrett, speaking from his personal experience of monitoring that acidity, responded that lake water in the Pit 10 years ago was reddish brown, but about 5 years ago the chemistry changed and showed improvement. The color changed toward blue-green and the pH level rose from a low of acidic 2.0 toward today’s slightly more alkaline 4.0 level. This was due to the addition of lime from a water treatment plant, year after year, which dropped the iron and arsenic levels in addition to raising the pH in the pit lake water. The polluting copper levels, however, have not declined probably due to copper continuing to leach from the pit walls and into the water.

A question was raised about the tonnage of the copper that has come out of the Berkeley mine. Garrett did not have those figures on hand, but said it was extensive, not only from the mining, but also from copper extracted from the pit lake water through a precipitation or plating process. Within the first year of operation, the pit extracted 17,000 tons of ore per day at a grade of 0.75% copper. Over the twenty-seven years it was active (1955 to 1982), the Berkeley open pit mine produced over one billion tons of ore, including copper, lead, zinc, gold, and manganese.

Wildlife, especially bird populations, suffered die-offs in earlier years. But now sounds and other deterrent systems drive away migrating birds so they do not suffer as much from the Pit water.

The interesting questions continued and ranged from the potential to mine the Pit’s lake sludge for rare earth and other metals (yes, possibly in the future), to availability of Yogo sapphire mining (currently in a ten-acre area controlled by a homeowners association).

Wrap-up

President Ken Reynolds thanked Garrett for his wonderful program. Ken, like a large number of the MSDC members, spoke about his own visits to Montana and his appreciation for both the need for minerals and the need for an environment free of contamination. Garrett said he participates in frequent meetings with citizens who by and large also affirm both sides of the mining-environment spectrum and acknowledged his Department of Environmental Quality aims to strike a balance between mining and recreation. Ken closed the meeting and thanked all for attending.

[Editorial note: MSDC hopes the synopsis provided here inspires readers to actually click on the link provided below which gives access to the entirety of Garrett’s recorded presentation. His talk is rich in the geology, history, and products which derive from a large number of diverse hard rock mines and which give Montana its well-earned name, the Treasure State.]

Here is the link for gaining access to Garrett Smith’s entire MSDC presentation: