Beryllium and the James Webb Space Telescope

by Ken Rock, MSDC Newsletter Editor

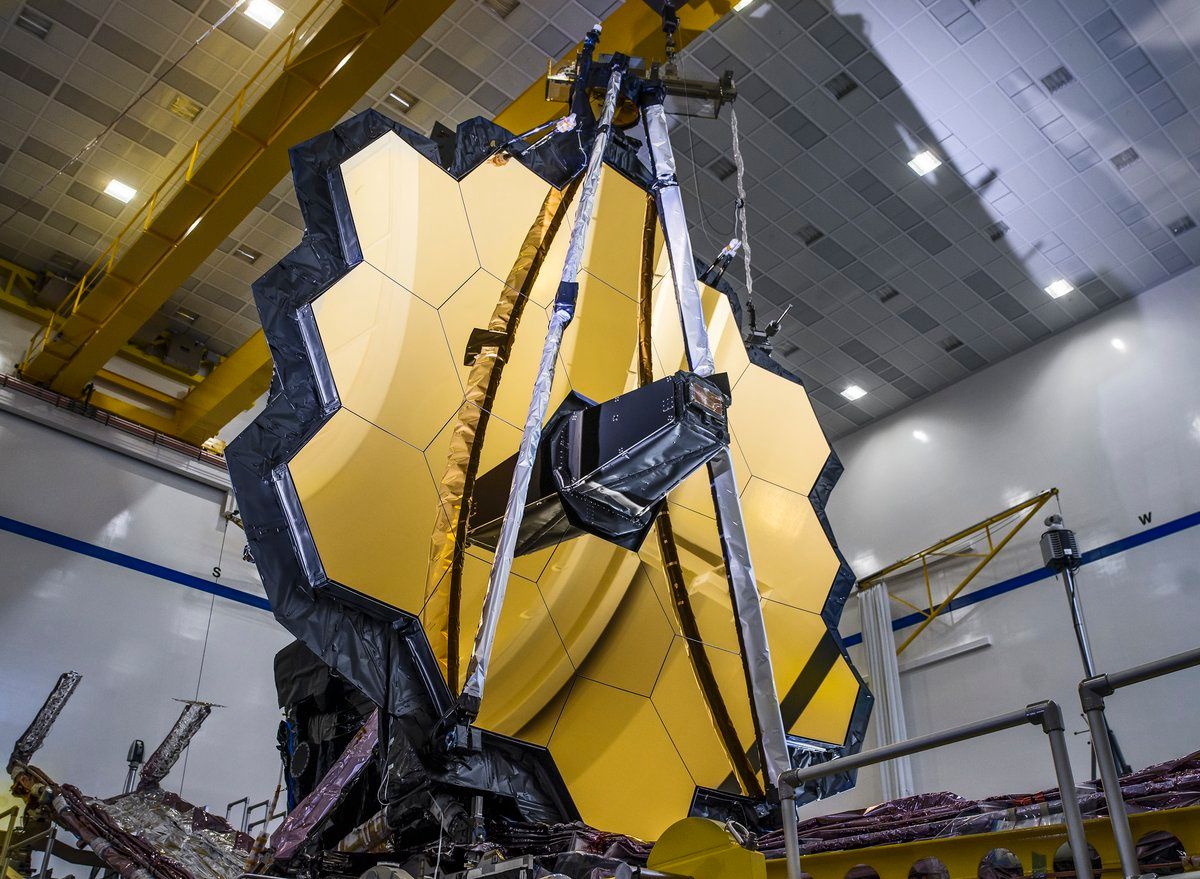

When the James Webb Space Telescope (JWST) launched into space on Christmas Day, 2021, it carried 18 gold-plated hexagonal mirrors that will help astronomers see back more than 13 billion years – a time when the first stars and galaxies were forming from the darkness of the early universe. The mirrors comprising this time machine are made of beryllium, a relatively rare silvery-white metal that is one-third lighter than aluminum and around six times stiffer than steel (though not as strong), which provides needed dimensional stability for the mirror.

Amazing Engineering and Technology

The JWST is the largest and most powerful space telescope ever constructed. Its enormous size and the frigid temperature required for its operation presented extraordinary engineering challenges. Working with a contractor nearly 20 years ago, NASA engineered a special grade of gas-atomized beryllium which is lightweight and has the properties needed for the telescope’s primary mirror. The 18 gold-covered beryllium mirror segments comprising the mirror will allow scientists to see farther in the universe than ever before – with nearly 100 times more power than the Hubble telescope. The amazing engineering that went into this $10 billion and 25-year project is highlighted in a YouTube video here.

Another big challenge was to figure out how to allow the 6.5 meter (21.3 feet) mirror to be loaded onto a rocket for launch and subsequent deployment in space. Each of the 18 hexagonal segments must maintain its exact shape even at the very low temperatures of space and had to be light enough to be carried into orbit.

The solution was to design the large mirror so it could be carefully folded into smaller pieces. These 18 main mirror segments were designed to form a parabolic mirror that will concentrate the light on the secondary mirror, which then will reflect to the actual instruments. Aligning and focusing these 18 individual mirror segments to that they could form a single high-fidelity image was a major technological achievement of the JWST.

The mirrors were ground to nano-level precision, a remarkable achievement by itself. But we all know that metals shrink when they cool. Although a very useful property of beryllium is that it does not change very much when it is cooled to very low temperature, it still does change. This meant that the beryllium, when polished at room temperature, had to be polished to the wrong shape so that when it cooled down, it would be in the right shape. New technology had to be developed for that to happen. 1 A short video showing the deployment sequence for the JWST may be seen here.

Why Beryllium?

Beryllium is a very light metal that has a very high melting point at 2349 °F (1287 °C). The combination of its light weight and high melting point makes it valuable for making metal alloys which are used in electronic and electrical components, aerospace, automobiles, computers, oil and gas drilling equipment, and telecommunications. The silvery-white metal is classified by the U.S. Department of Defense as a strategic and critical material because it is used in products that are vital to national security.

Beryllium appealed to the engineers of the JWST because the stiff, lightweight metal maintains a stable shape even at extremely low temperatures. Insulated by a sun shield, JWST will operate at about 30 K (-406°F) as it orbits about 1 million miles from Earth. The metal is also tough enough to withstand collisions with tiny particles in space called micrometeoroids. A very thin layer of gold (0.1 microns) was applied to the surface of the polished beryllium mirror segments because it is an excellent reflector of the infrared spectrum and is unreactive. This thin layer required only 48.2 grams of gold, about the size of a golf ball.

Source of Beryllium Used in the JWST

The beryllium used in JWST came from the area shown in the photo below — the Spor Mountain mining area in the west-central area of Utah. The Spor Mountain Formation is a volcanic sequence that hosts the largest deposit of beryllium in the world. The Spor Mountains are the largest source of beryllium in the United States and the world.

According to some estimates, the Spor Mountains yield about 85 percent of the total produced globally. Other countries that produce beryllium include China (primarily) and Mozambique.

In the rocky ground around Spor Mountain, most beryllium is found within minerals such as bertrandite and beryl that formed around 25 million years ago as lava cooled after a volcanic eruption. After excavation, the bertrandite ore gets shipped to a nearby plant, where it is crushed into a powder and mixed with water as part of a process to separate and concentrate the beryllium.

NASA has a long history of using beryllium from Spor Mountain. In the agency’s early years, engineers used it in the heat shield for the Project Mercury return capsule. Project Gemini used it in shingles that protected parachute enclosures. Later it was used in the space shuttles, the International Space Station, the Spirit and Opportunity rovers that landed on Mars, the Spitzer Space Telescope, and other missions.

Beryllium Mining and Minerals

The most well known mineral containing beryllium is beryl which is found in granites and coarse-grained igneous rocks known as pegmatites. Colored, transparent varieties of beryl may be gems, such as emerald (green), aquamarine (blue-green), heliodor (yellow), and morganite (pink). Some of the oldest known gems were mined by the Assyrians, Babylonians, Hittites, and Persians between 5000 and 400 B.C.E.

In addition to beryl, beryllium is found in the mineral bertrandite, which is the primary source of the beryllium used on the JWST. Bertrandite is found in certain volcanic rocks derived from granite.

Unlike beryl, in which the mineral can be identified by color and crystal structure, bertrandite mineralization cannot be recognized by the naked eye. In fact, the bertrandite ore found in the Spor Mountains is very similar to clay (an aluminum silicate) and looks like common dirt except it has a slight pinkish color. It’s also associated with fluorspar or fluorite, which often has a deep blue to violet color. One is tempted to think the more colorful fluorite is the mineral we want, but it’s actually the crumbly pink coating found on the fluorite nodules. Elsewhere in the Spor Mountains, the fluorite has been mined commercially.

To determine where to mine, geologic and geochemical evaluations are conducted on a specific area, followed by a drilling program to determine if an economic ore body exists. Detailed drilling and sample analysis allows maps to be prepared that are used to plan the mining and processing operations.

Ore is typically mined from linear open pits that follow the strike of the tilted ore-bearing tuff. Deposits are mined to shallow depths (very approximately, 30-50 m). Depth is limited by the cost of stripping hard rhyolite caprock. Because of the irregular ore-grade distribution in the ground, the ore is mined from areas defined by drill data and placed in a stockpile in layers to obtain a more homogeneous blend. Further drilling, sampling, and assaying of the stockpiled ore is then performed to determine the ore-grade distribution throughout the stockpile. On the basis of the grade distribution, stockpiled ore is selectively trucked to the mill for further processing.

Uses of Beryllium

Most beryllium is used in metal alloys, which account for more than 70% of world consumption. Because beryllium is very light and has a high melting temperature, it is an ideal metal for use in the aerospace and defense industry. However, unlike its use in the JWST, beryllium is almost always alloyed with other metals.

Beryllium metal also has the interesting characteristic of being elastic. Consequently, it is used in the manufacture of springs, gears and other machine components that need a degree of elasticity. Another everyday application is in the manufacture of gasoline pumps, because an alloy of copper and beryllium (beryllium bronze) does not spark when hit against other metals, nor emit sparks from static electricity. Rods made of beryllium metal and oxide are used to control nuclear reactions, because beryllium absorbs neutrons better than any other metal.

Beryllium and some beryllium compounds are toxic and must be handled carefully. Workplace related exposures to dusts or fumes of beryllium and beryllium compounds are known to cause serious health problems, such as cancer or chronic beryllium disease, which is an immune system response that can damage the lungs. Proper workplace practices prevent these exposures.

Sources Cited:

- Ken Sembach's presentation "Is Astronomy Ready for the James Webb Space Telescope?" from the 2018 Exploring Space Lecture Series, sponsored by the Smithsonian's National Air & Space Museum.

- https://geology.com/usgs/beryllium/